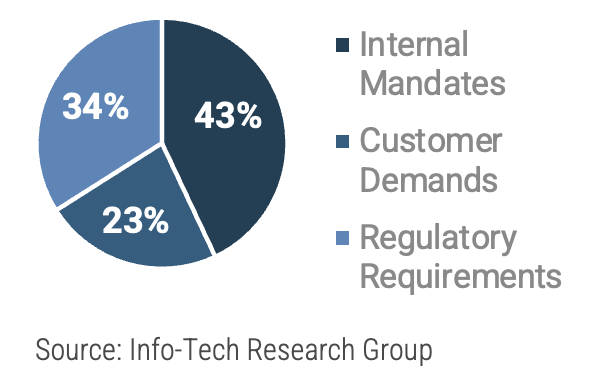

- Recent crises have increased executive awareness and internal pressure to create a business continuity plan (BCP).

- Manufacturing-driven regulations require evidence of sound business continuity practices.

- Customers demand their vendors provide evidence of a workable BCP prior to signing a contract.

- IT leaders, because of their cross-functional view and experience with incident management and DR, are often asked to lead BCP efforts.

Our Advice

Critical Insight

- BCP requires input from multiple departments with different and sometimes conflicting objectives. There are typically few, if any, dedicated resources for BCP, so it can't be a full-time, resource-intensive project.

- As an IT leader you have the skill set and organizational knowledge to lead a BCP project, but ultimately, business leaders need to own the BCP – they know their processes and their requirements to resume business operations better than anyone else.

- The traditional approach to BCP is a massive project that most organizations can’t execute without hiring a consultant. To execute BCP in-house, carve up the task into manageable pieces as outlined in this blueprint.

Impact and Result

- Implement a structured and repeatable process that you apply to one business unit at a time to keep business continuity planning efforts manageable.

- Use the results of the pilot to identify gaps in your recovery plans and reduce overall continuity risk while continuing to assess specific risks as you repeat the process with additional business units.

- Enable business leaders to own the BCP going forward. Develop a template that the rest of the organization can use.

- Leverage BCP outcomes to refine IT DRP recovery objectives and achieve DRP-BCP alignment.

Workshop: Develop a Business Continuity Plan for Manufacturing

Workshops offer an easy way to accelerate your project. If you are unable to do the project yourself, and a Guided Implementation isn't enough, we offer low-cost delivery of our project workshops. We take you through every phase of your project and ensure that you have a roadmap in place to complete your project successfully.

Module 1: Define BCP Scope, Objectives, and Stakeholders

The Purpose

Define BCP scope, objectives, and stakeholders.

Key Benefits Achieved

Prioritize BCP efforts and level-set scope with key stakeholders.

Activities

Outputs

Assess current BCP maturity.

- BCP Maturity Scorecard: measure progress and identify gaps.

Identify key business processes to include in scope.

- Business process flowcharts: review, optimize, and knowledge-transfer processes.

Flowchart key business processes to Identify business processes, dependencies, and alternatives.

- Identify workarounds for common disruptions for day-to-day continuity.

Module 2: Define RTOs and RPOs Based on Your BIA

The Purpose

Define RTOs and RPOs based on your BIA.

Key Benefits Achieved

Set recovery targets based business impact, and illustrate the importance of BCP efforts via the impact of downtime.

Activities

Outputs

Define an objective scoring scale to indicate different levels of impact.

- BCP Business Impact Analysis: objective scoring scale to assess cost, goodwill, compliance, and safety impacts.

Estimate the impact of downtime.

- Apply the scoring scale to estimate the impact of downtime on business processes.

Determine acceptable RTO/RPO targets for business processes based on business impact

- Acceptable RTOs/RPOs to dictate recovery strategy.

Module 3: Create a Recovery Workflow

The Purpose

Create a recovery workflow.

Key Benefits Achieved

Build an actionable, high-level recovery workflow that can be adapted to a variety of different scenarios.

Activities

Outputs

Conduct a tabletop exercise to determine current recovery procedures.

- Recovery flow diagram – current and future states.

- Identify gaps and recovery risks.

Identify and prioritize projects to close gaps and mitigate recovery risks.

- Create a project roadmap to close gaps.

Evaluate options for command centers and alternate business locations (i.e. BC site).

- Evaluate requirements for alternate business sites.

Module 4: Extend the Results of the Pilot BCP and Implement Governance

The Purpose

Extend the results of the pilot BCP and implement governance.

Key Benefits Achieved

Outline the actions required for the rest of your BCMS and the required effort to complete those actions, based on the results of the pilot.

Activities

Outputs

Summarize the accomplishments and required next steps to create an overall BCP.

- Pilot BCP Executive Presentation

Identify required BCM roles.

- Business Continuity Team Roles & Responsibilities

Create a plan to update and maintain your overall BCP.

- 3. Maintenance plan and BCP templates to complete the relevant documentation (BC Policy, BCP Action Items, Recovery Workflow, etc.)

Develop a Business Continuity Plan for Manufacturing

Streamline the traditional approach to make BCP development manageable and repeatable.

EXECUTIVE BRIEF

Analyst Perspective

A BCP touches every aspect of your organization, making it potentially the most complex project you'll take on. Streamline this effort or you won't get far.

None of us needs to look very far to find a reason to have an effective business continuity plan (BCP).

From pandemics to natural disasters to supply chain disruptions to IT outages, there's no shortage of events that can disrupt your complex and interconnected business processes. How in the world can anyone build a plan to address all these threats?

Don't try to boil the ocean. Use these tactics to streamline your BCP project and stay on track:

- Focus on one business unit at a time. Keep the effort manageable, establish a repeatable process, and produce deliverables that provide a starting point for the rest of the organization.

- Don't start with an extensive risk analysis. It takes too long and at the end you'll still need a plan to resume business operations following a disruption. Rather than trying to predict what could cause a disruption, focus on how to recover.

- Keep your BCP documentation concise. Use flowcharts, checklists, and diagrams instead of traditional manuals.

No one can predict every possible disruption, but by following the guidance in this blueprint, you can build a flexible continuity plan that allows you to withstand the threats your organization may face.

Frank Trovato

Research Director,

IT Infrastructure & Operations Practice Info-Tech

Research Group

Andrew Sharp

Senior Research Analyst,

IT Infrastructure & Operations Practice Info-Tech

Research Group

Executive Summary

Your Challenge

|

Common Obstacles

|

Info-Tech's Approach

|

Info-Tech Insight

As an IT leader you have the skill set and organizational knowledge to lead a BCP project, but you must enable leaders to own their department's BCP practices and outputs. They know their processes and, therefore, their requirements to resume business operations better than anyone else.

Use this research to create business unit BCPs and structure your overall BCP

A business continuity plan (BCP) consists of separate but related sub-plans, as illustrated below. This blueprint enables you to:

- Develop a BCP for a selected business unit (as a pilot project), and thereby establish a methodology that can be repeated for remaining business units.

- Through the BCP process, clarify requirements for an IT disaster recovery plan (DRP). Refer to Info-Tech's Disaster Recovery Planning workshop for instructions on how to create an IT DRP.

- Implement ongoing business continuity management to govern BCP, DRP, and crisis management.

Overall Business Continuity Plan

IT Disaster Recovery Plan

A plan to restore IT application and infrastructure services following a disruption.

Info-Tech's Create a Right-Sized Disaster Recovery Plan blueprint provides a methodology for creating the IT DRP. Leverage this blueprint to validate and provide inputs for your IT DRP.

BCP for Each Business Unit

A set of plans to resume business processes for each business unit. This includes:

- Identifying business processes and dependencies.

- Defining an acceptable recovery timeline based on a business impact analysis.

- Creating a step-by-step recovery workflow.

Crisis Management Plan

A plan to manage a wide range of crises, from health and safety incidents to business disruptions to reputational damage.

Info-Tech's Implement Crisis Management Best Practices blueprint provides a framework for planning a response to any crisis, from health and safety incidents to reputational damage.

IT leaders asked to develop a BCP should start with an IT DRP

It's a business continuity plan. Why should you start continuity planning with IT?

- IT services are a critical dependency for most business processes. Creating an IT DRP helps you mitigate a key risk to continuity quicker than it takes to complete your overall BCP, and you can then focus on other dependencies such as people, facilities, and suppliers.

- A BCP requires workarounds for IT failures. But it's difficult to plan workarounds without a clear understanding of the potential IT downtime and data loss. Your DRP will answer those questions, and without a DRP, BCP discussions can get bogged down in IT discussions. Think of payroll as an example: if downtime might be 24 hours, the business might simply wait for recovery; if downtime might be a week, waiting it out is not an option.

- As an IT manager, you can develop an IT DRP primarily with resources within your control. That makes it an easier starting point and puts IT in a better position to shift responsibility for BCP to business leaders (where it should reside) since essentially the IT portion is done.

Create a Right-Sized Disaster Recovery Plan today.

Business continuity management in manufacturing requires proactive planning

Three components of crisis management that manufacturing companies should consider.

-

Emergency Planning

This addresses immediate response to the situation. It includes procedures and policies to effectively respond to chaotic situations such as natural disasters, security incidents, staff well-being, and public health issues. Business leads should make sure that appropriate business continuity measurements, such as allocation of emergency response team, evacuation protocols, and communication plans, are in place. -

Business Continuity Management

Business continuity management (BCM) involves procedures to ensure that business will maintain its integrity while leaders are handling the situation. BCM includes identification of the critical systems, resources, and processes that help the company sustain its critical operations. By enabling BCM, you will enable strategies and processes to minimize the potential impacts of disruptions. -

Business Integrity

The COVID-19 pandemic taught businesses the critical need for business continuity planning, including the development of contingency plans to provide seamless support to front line and other staff. Emergency notification systems, simulation software solutions, communication platforms, remote monitoring systems, and mobile applications are a few examples of the tools that are necessary to enable manufacturing companies to run efficient business continuity.

Business continuity planning in manufacturing presents several unique challenges

There are key differences between the emergency preparedness challenges of manufacturing and other industries.

Business Resiliency

Within the manufacturing industry, companies should make sure that their stakeholder groups, including manufacturers, suppliers, and customers, are on the same page. Service level agreements (SLAs) should be formalized and realistic considering ideal situations and potential compromising cases. An enterprise's emergency team should be ready to restore services ASAP before the service quality gets impacted.

Manufacturing Products

Defective manufacturing goods can lead to a severely negative impact, and even failure of the business. Pricing fluctuation can hugely affect a company's profit margin. Moreover, financial instabilities have introduced an added challenge, leading to uncertainty for allocation of credit to manufacturing businesses.

Product Dependency

In a critical situation, a manufacturing company cannot finish the production of its product. When the product is not produced, the company cannot comply with its commitment for delivery. When it does not deliver the product on time, profit goes down. These series of failures lead to the loss of revenue and decreased customer satisfaction.

Crisis management teams within manufacturing companies should craft mitigation strategies against such scenarios.

Various manufacturing stakeholders tie into the challenges of running an efficient BCP

Manufacturing owners and executives

A BCP program requires up-front investment, which will make it challenging to get executives' buy-in. Manufacturing is heavily dependent on technology and business leaders would like to invest more in their facilities than just contingency plans for a potential rainy day.

Customers

The ultimate goal of manufacturing companies is brand reputation and customer satisfaction. If the quality of a product reduces due to a crisis, it negatively impacts customer satisfaction and jeopardizes the whole business. Therefore, manufacturing companies need to have solid BCP protocols to ensure the quality of their products and the timeliness of product delivery to their clients.

Workforce

Labor unions should be trained for BCP protocols. Manufacturing companies should have efficient BCP for the times when there is an employee shortage due to natural disasters (e.g. flood, storm, and pandemics) or socio-political unrest (e.g. labor strikes).

Investors

Economy volatility plays a pivotal role in investments and manufacturing relies heavily on investments. There is a risk of low participation from investors during times of financial difficulties (e.g. recession), which then affects the financial liquidity of companies. Having a robust BCP helps manufacturing companies reassure their investors that they are prepared for a crisis and can handle uncertainties.

Modernize the BCP

If your BCP relies heavily on paper-based processes as workarounds, it's time to update your plan.

Back when transactions were recorded on paper and then keyed into the mainframe system later, it was easier to revert to deskside processes. There is very little in the way of paper-based processes anymore, and as a result, it is increasingly difficult to resume business processes without IT.

Think about your own organization. What IT system(s) are absolutely critical to business operations? While you might be able to continue doing business without IT, this requires regular preparation and training. It's likely a completely offline process and won't be a viable workaround for long even if staff know how to do the work. If your data center and core systems are down, technology-enabled workarounds (such as collaboration via mobile technologies or cloud-based solutions) could help you weather the outage, and may be more flexible and adaptable for day-to-day work.

The bottom line:

Technology is a critical dependency for business processes. Consider the role IT systems play as process dependencies and as workarounds as part of continuity planning.

Info-Tech's approach

The traditional approach to BCP takes too long and produces a plan that is difficult to use and maintain.

The problem: You need to create a BCP but don't know where to start.

- BCP is being demanded more and more to comply with regulations, mitigate business risk, meet customer demands, and obtain insurance.

- IT leaders are often asked to lead BCP.

The Complication: A traditional BCP process takes longer to show value.

- Traditional consultants don't usually have an incentive to accelerate the process.

- At the same time, self-directed projects with no defined process go months without producing useful deliverables.

- The result is a dense manual that checks boxes but isn't maintainable or usable in a crisis.

The Info-Tech difference: Use Info-Tech's methodology to right-size and streamline the process.

- Reduce required effort. Keep the work manageable and maintain momentum by focusing on one business unit at a time; allow that unit to own their BCP.

- Prioritize your effort. Evaluate the current state of your BCP to identify the steps that are most in need of attention.

- Get valuable results faster. Functional deliverables and insights from the first business unit's BCP can be leveraged by the entire organization (e.g. communication, assessment, and business continuity site strategies).

Expedite BCP development

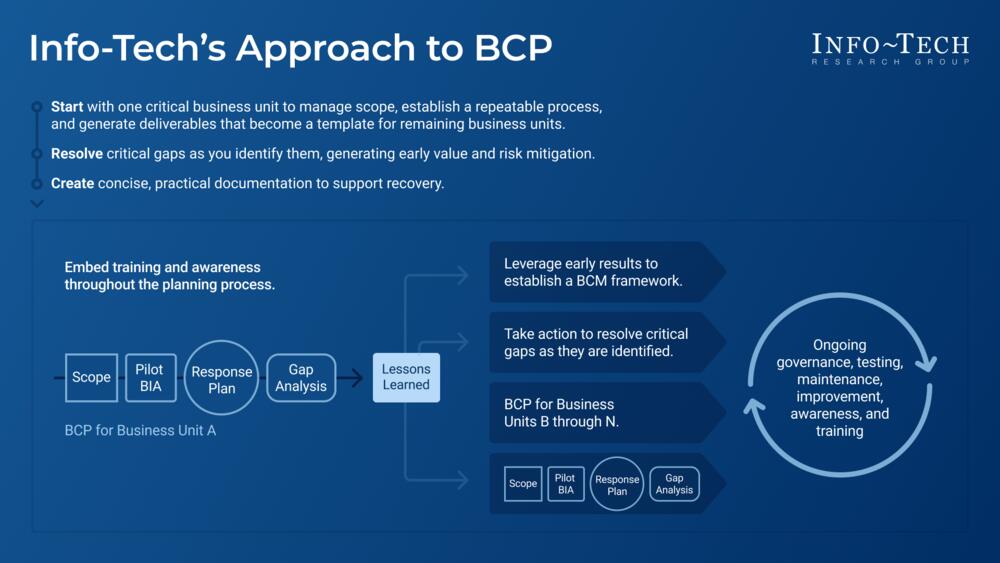

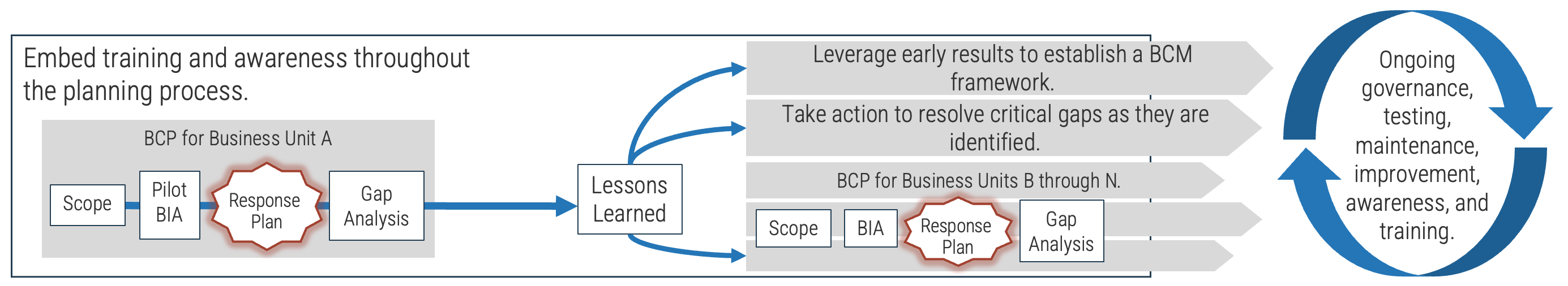

Info-Tech's Approach to BCP:

- Start with one critical business unit to manage scope, establish a repeatable process, and generate deliverables that become a template for remaining business units.

- Resolve critical gaps as you identify them, generating early value and risk mitigation.

- Create concise, practical documentation to support recovery.

By comparison, a traditional BCP approach takes much longer to mitigate risk:

- An extensive, up-front commitment of time and resources before defining incident response plans and mitigating risk.

- A “big bang” approach that makes it difficult to predict the required resourcing and timelines for the project.

Case study

A manufacturing company engaged Info-Tech to develop a BCP to make them ready to deal with uncertainties.

INDUSTRY: Manufacturing

SOURCE: Info-Tech Research Group

ChallengeA global medium-sized automotive manufacturing company needed to develop a BCP to safeguard its production during crisis. The company relied heavily on a group of suppliers, making a holistic BCP strategy challenging. Production was also heavily automated, and any failure in its systems would cause a huge downtime. As the business was digitally connected to suppliers, the company was vulnerable to cybersecurity attacks. |

SolutionThe business and IT leaders engaged in a BIA to determine their processes and dependencies and to define acceptable recovery and repatriation gaps. The team identified alternative sources for critical raw materials. They were trained on strategies for cross training and communication of initiatives. |

ResultThrough a proactive BCP implementation, the company now has a higher resilience to potential disruptions. If an unexpected event occurs, the company can swiftly activate its contingency plans. If a supply chain is affected by a natural disaster, the company will engage its alternate suppliers to ensure minimal disruptions to production. This allows the company to keep a good rapport with its customers and minimize reputational damage. |

Project Overview: BCP

Phases |

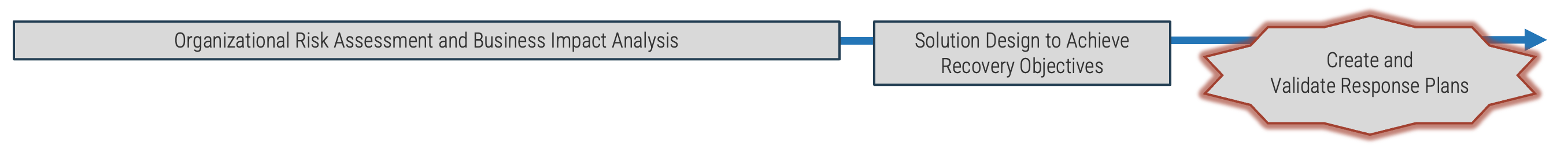

Phase 1:Identify BCP Maturity and Document Process Dependencies |

Phase 2:Conduct a BIA to Determine Acceptable RTOs and RPOs |

Phase 3:Document the Recovery Workflow and Projects to Close Gaps |

Phase 4:Extend the Results of the Pilot BCP and Implement Governance |

Steps |

1.1: Assess current BCP maturity 1.2: Establish the pilot BCP team 1.3: Identify business processes, dependencies, and alternatives |

2.1: Define an objective impact scoring scale 2.2: Estimate the impact of downtime 2.3: Determine acceptable RTO/RPO targets |

3.1: Determine current recovery procedures 3.2: Identify and prioritize projects to close gaps 3.3: Evaluate business continuity site and command center options |

4.1: Consolidate BCP pilot insights to support an overall BCP project plan 4.2: Outline a BCM program 4.3: Test and maintain your BCP |

Tools and Templates |

BCP Business Impact Analysis Tool Maturity Scoreboard Pilot Project Charter Business Process Workflows Examples | BCP Business Impact Analysis Tool | BCP Business Impact Analysis Tool Tabletop Planning Template Recovery Workflow Examples BCP Project Roadmap | Results Presentation BCP Summary Business Continuity Teams and Roles BCP Recovery Playbook for Manufacturing |

Blueprint deliverables

Each step of this blueprint is accompanied by supporting deliverables to help you accomplish your goals:

BCP Business Impact Analysis Tool

Conduct and document a BIA using this document.

BCP Recovery Workflow Example

Model your own recovery workflows on this example.

BCP Project Roadmap

Use this tool to prioritize projects that can improve BCP capabilities and mitigate gaps and risks.

BCP Relocation Checklists

Plan for and manage a site relocation – whether to an alternate site or work from home.

Key deliverable:

Summarize your organization's continuity capabilities and objectives in a 15-page, easy-to-consume template.

This document consolidates data from the supporting documentation and tools to the right.

Insight summary

Focus less on risk, and more on recovery

Avoid focusing on risk and probability analysis to drive your continuity strategy. You never know what might disrupt your business, so develop a flexible plan to enable business resumption regardless of the event.

Small teams = good pilots

Choose a small team for your BCP pilot. Small teams are better at trialing new techniques and finding new ways to think about problems.

Calculate downtime impact

Develop and apply a scoring scale to develop a more-objective assessment of downtime impact for the organization. This will help you prioritize recovery.

It's not no, but rather not now…

You can't address all the organization's continuity challenges at once. Prioritize high-value, low-effort initiatives and create a long-term roadmap for the rest.

Show value now

Get to value quickly. Start with one business unit with continuity challenges, and a small, focused project team who can rapidly learn the methodology, identify continuity gaps, and define solutions that can also be leveraged by other departments right away.

Lightweight testing exercises

Outline recovery capabilities using lightweight, low risk tabletop planning exercises. Our research shows tabletop exercises increase confidence in recovery capabilities almost as much as live exercises, which carry much higher costs and risks.

Blueprint benefits

Demonstrate compliance with demands from regulators and customers

- Develop a plan that satisfies auditors, customers, and insurance providers who demand proof of a continuity plan.

- Demonstrate commitment to resilience by identifying gaps in current capabilities and projects to overcome those gaps.

- Empower business users to develop their plans and perform regular maintenance to ensure plans don't go stale.

- Establish a culture of business readiness and resilience.

Leverage your BCP to drive value (business benefits)

- Enable flexible, mobile, and adaptable business operations that can overcome disruptions large and small. This includes making it easier to work remotely in response to pandemics or facility disruptions.

- Clarify the risk of the status quo to business leaders so they can make informed decisions on where to invest in business continuity.

- Demonstrate to customers your ability to overcome disruptions and continue to deliver your services.

Info-Tech's Advisory Services lead to measurable value

Info-Tech members told us they save an average of $44,522 and 23 days by working with an Info-Tech analyst on BCP.*

Why do members report value from analyst engagement?

- Expert advice on your specific situation to overcome obstacles and speed bumps.

- Structure the project and stay on track.

- Review project deliverables and ensure the process is applied properly.

* Based on client response data from Info-Tech's Measured Value Survey, following analyst advisory on BCP.

Info-Tech offers various levels of support to best suit your needs

DIY Toolkit

"Our team has already made this critical project a priority, and we have the tie and capability, but some guidance along the way would be helpful."

Guided Implementation

"Our team knows that we need to fix a process, but we need assistance to determine where to focus. Some check-ins along the way would help keep us on track."

Workshop

"We need to hit the ground running and get this project kicked off immediately. Our team has the ability to take this over once we get a framework and strategy in place."

Consulting

"Our team does not have the time or the knowledge to take this project on. We need assistance through the entirety of this project."

Diagnostics and consistent frameworks are used throughout all four options.

Guided Implementation

Your Trusted Advisor is a call away.

Scoping

Call 1: |

Business Processes and Dependencies

Calls 2-4: |

Conduct a BIA

Calls 5-7: |

Recovery Workflow

Calls 8-9: |

Documentation & BCP Framework

Call 10: |

A Guided Implementation (GI) is series of calls with an Info-Tech analyst to help implement our best practices in your organization.

A typical GI is 8 to 12 calls over the course of 4 to 6 months.